Plastic Fastener Screws for Retail POP Stand Construction Displays 31420

Double-flanged plastic screws are used to secure POP display components in retails. Threaded design ensures tight fits easy to install reusable for multiple displays.

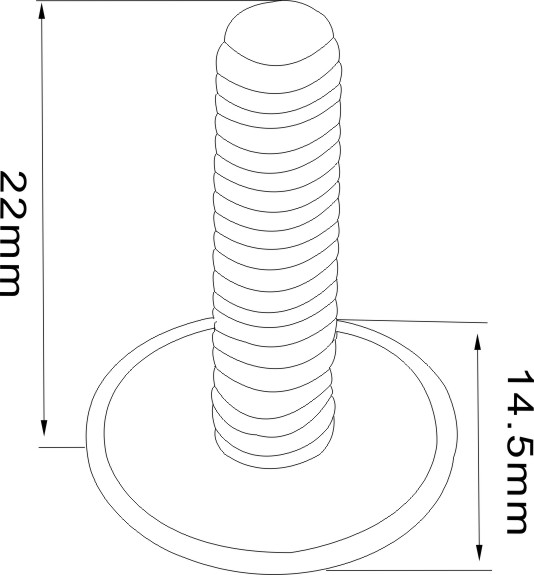

| Product Name | squeeze-on screw/nut |

| Product Code | 31420 |

| Color | natural colour |

| Material | PP |

| Size | Diameter 14.5mm, heigth:22mm |

| Sample | Available free sample |

| MOQ | 20,000 |

| Port | FOB Shanghai or Ningbo |

| Application | Supermarket,Retail Store,Shopping Mall,Exhibition,etc. |

product description

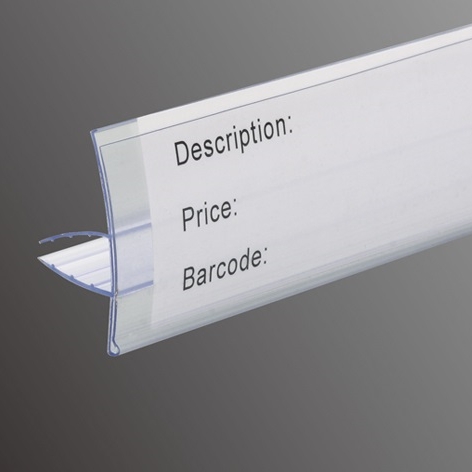

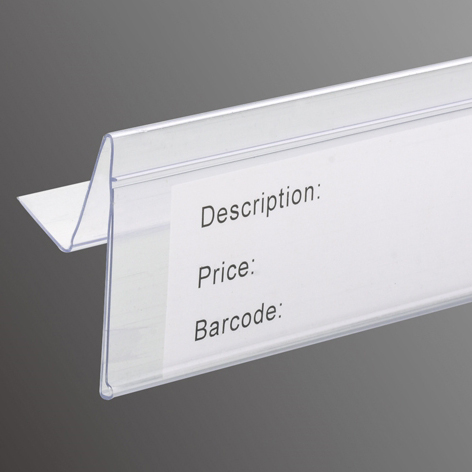

When building corrugated point-of-purchase (POP) displays for retail spaces, reliable fasteners are key to keeping stands stable. Our plastic fastener screws solve this: the threaded design screws securely into pre-drilled holes in corrugated board, while the dual flanges distribute pressure to prevent tearing.

Made of sturdy, clear plastic, these screws blend seamlessly with cardboard displays (so they don’t distract from product visibility) and are reusable across multiple display builds. Perfect for retail POP setups, they install quickly with no tools and can be long-lasting hold. Whether you’re assembling temporary promotional displays or semi-permanent retail fixtures, these screws add structural reliability without adding bulk.

Design Rendering

& Core Details

A clear visual presentation of structural highlights and functional features, helping you grasp key product attributes at a glance.

tailored customization services

IDmate's display accessories

Continuous Product Updates

Tianjie, the owner of the IDmate trademark, specializes in manufacturing identity (ID) accessories and point-of-sale (POS) display accessories. We are committed to regularly updating our product line and continuously developing new name badges, new badge reels, new label holders, and new display accessories. Each year, we collaborate with our customers to develop dozens of new product varieties.

Professional Design Team

Our team has over 20 years of experience in these fields. From design and mold development to production, we can customize products that fully meet customer requirements with meticulous attention to every detail. Examples include the world's smallest badge reel (with a diameter of just 18mm) and label holders designed for specialized applications. Customers can enjoy a hassle-free partnership with us, which is why they are always satisfied with our collaboration.

Flexibility with Minimum Order Quantities

By integrating factory and material resources, Tianjie helps customers avoid issues related to minimum order quantities (MOQ) by offering a variety of flexible solutions for smaller orders. For specific MOQ requirements, please inquire based on the exact product type, as minimum order quantities vary depending on the materials used and production processes involved.

Diverse Production Capacity

Tianjie offers comprehensive production capabilities, including injection molding, extrusion, ultrasonic welding, high-frequency welding, and automatic folding. We handle multi-material and multi-process production, with most procedures completed in-house. For outsourced processes, we rely on trusted long-term partners to ensure seamless operations equivalent to in-house manufacturing.