If you choose the right type and use them according to the instructions, adhesive hooks can protect your walls. Brands like Command, LCHOME, and IDmate hooksare known for their special features and good results. Many shop owners worry about damaging walls, difficulty in removal, and the need for prior wall preparation. They want to find hooks that allow for easy and safe replacement of display items. Choosing the right hooks for your walls can prevent problems and keep your shelves neat and attractive.

Common worries are:

- Poor adhesive strength

- Damage to walls when removing hooks

- Need for prior wall preparation

Key Takeaways

- Choose adhesive hooks suitable for your wall type. This helps prevent damage. Glass and tile are the best surfaces.

- Clean the wall thoroughly before installing the hooks. Use a mixture of isopropyl alcohol and water for cleaning. This allows the hooks to adhere more securely.

- Read and follow the manufacturer’s instructions. Always do this when installing or removing hooks. This protects your walls and extends the lifespan of the hooks.

- Check the weight limit before using the hooks. Do not overload them. This protects your items and prevents accidents.

- Consider factors such as humidity and temperature. These factors can affect the adhesive strength and lifespan.

Best adhesive hooks for no wall damage

Top brands overview

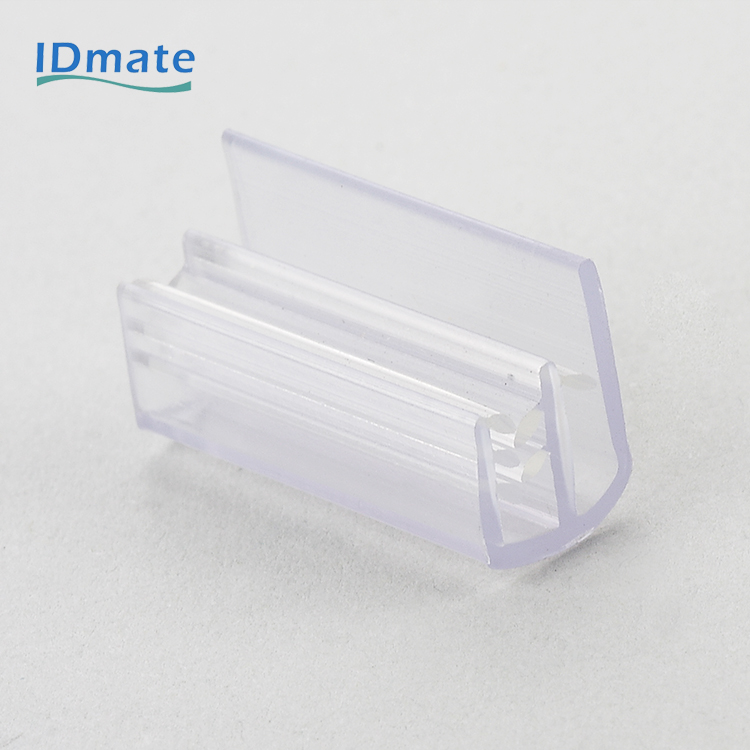

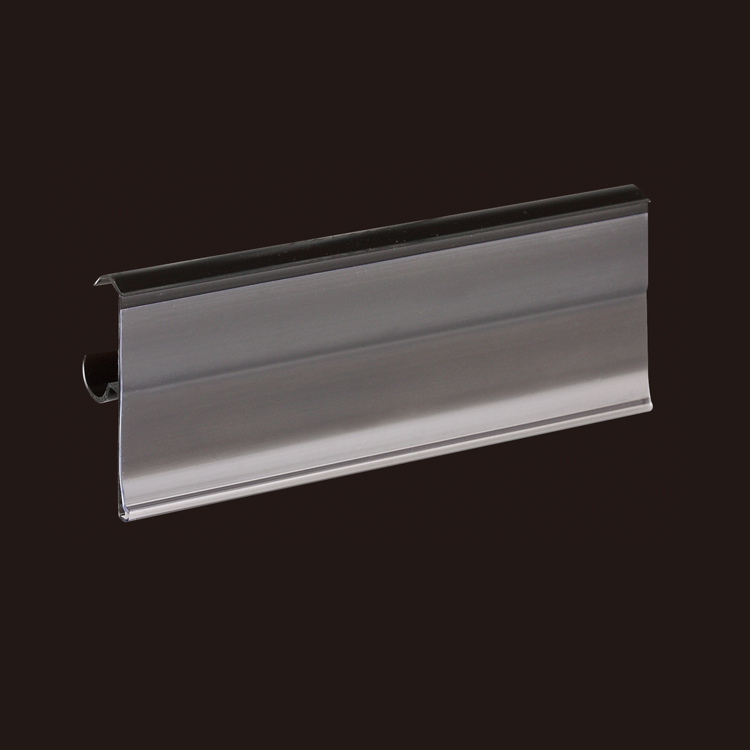

Shop owners need reliable shelf hooks. Command, LCHOME, and IDmate are three popular brands. Each brand helps protect walls and facilitates easy replacement of display items.

| Brand | Damage Prevention Rating | Notes |

|---|---|---|

| Command | High | Suitable for damage-free hanging |

| LCHOME | Not specified | Commonly used in stores |

| IDmate | High | Known for strong quality and service |

Command hooks are known for preventing wall damage. Many stores use Command because they are easy to remove and work well. LCHOME is a more economical option for lightweight items. IDmate is unique in that it produces strong and durable hooks and focuses on quality control. IDmate’s products are sold in over 30 countries and they collaborate with numerous businesses.

The IDmate team has over 20 years of experience in hook manufacturing. Their hooks are tested to be strong, durable, and reliable. Customers appreciate IDmate’s quick response and customized services.

Tip: Store owners should choose brands that are durable and provide good service.

Key features to consider

Choosing the right hooks protects walls and keeps displays secure. Several factors are crucial:

- Wall type affects hook adhesion. Smooth tile surfaces work best. Painted drywall requires the paint to be completely dry before use.

- Proper hook installation prevents wall damage. Clean and dry the wall surface before installation.

- Sturdy hooks and safety labels are hallmarks of quality products. Choose hooks that have undergone sunlight exposure and fire safety testing.

| Certification/Standard | Description |

|---|---|

| FMVSS | Used for cars |

| FAR, BMS, DMS, NFPA | Equipment fire safety |

| ISO 4892, part II | Tests material durability under sunlight |

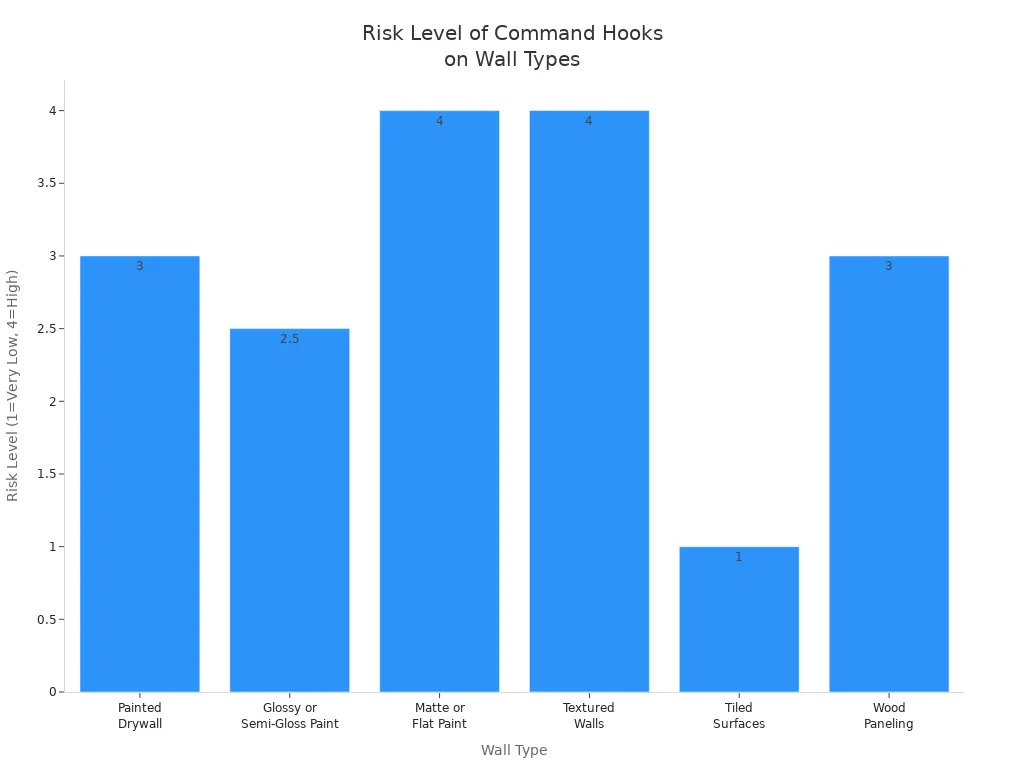

Customers have indicated that choosing hooks that match the wall surface is very important. The table below shows how Command hooks perform on different wall surfaces:

Stores should check if the hooks are suitable for the wall surface before use. Frequently replacing hooks increases costs, so purchasing high-quality hooks can save money.

IDmate’s features include ISO9001 certification, sturdy packaging, and fast shipping. Their hooks are safe and reliable and can be used directly in stores.

Note: Always follow the manufacturer’s instructions for best results and long-lasting display.

Choosing adhesive hooks for your wall

Matching hooks to surfaces

Store owners need to choose hooks that are suitable for their walls. Smooth surfaces such as glass, tiles, and polished wood work best. Adhesive hooks adhere strongly to these surfaces. Painted drywall walls can also be used if the paint is dry and the wall is clean. Hooks may not adhere securely to rough or dusty walls. Newly painted walls may also cause the hooks to fall off. The table below shows how the hooks perform on different wall surfaces:

| Surface Type | Performance Description |

|---|---|

| Smooth Surfaces | Adhesive hooks adhere best and can support heavier items. |

| Textured Surfaces | Hooks have weaker adhesion, especially on newly painted or dusty surfaces. |

Tip: Clean the wall surface before using adhesive hooks. Dirt and dust will reduce the hook’s adhesive strength.

Weight and size considerations

Store shelves display a variety of merchandise. Owners should check the weight limit of each hook. Small hooks are suitable for hanging lightweight labels or signs. Larger hooks are better for hanging heavier items. You can find the weight limit on the packaging. If the item being hung is too heavy, the hook may detach and damage the display. Choosing the right size ensures a safe and tidy display.

- Weigh items before hanging them.

- Use small hooks for lightweight items and large hooks for heavier items.

- Do not hang too many items on a single hook.

Environmental factors

The store environment affects the effectiveness of adhesive hooks. Humidity and temperature can weaken the adhesive. High humidity can soften the glue. Low temperatures can cause the hooks to lose their adhesiveness. Hooks perform best under normal weather conditions. The ideal temperature range is 15º to 25º C (59º to 77º F). The ideal humidity range is 40% to 60%.

Store owners should keep the area dry and maintain good air circulation. This helps extend the lifespan of the hooks and ensures they securely hold items.

Note: Not all adhesives are suitable for all wall surfaces. Choosing the right adhesive can prevent problems and maintain the aesthetics of the shelving.

Applying adhesive hooks safely

Preparing the wall

Store owners need to prepare the wall surface before using adhesive hooks. Proper preparation prevents damage and helps the hooks adhere better. Follow these steps:

- Do not use adhesive hooks on uneven surfaces, wallpaper, or newly painted walls. Oil-based paint needs at least a week to fully dry. Latex paint needs a month to fully dry.

- Clean the wall with a 50/50 mixture of isopropyl alcohol and water. This mixture removes grease and dirt.

- If there is a lot of grease, use a degreaser first. Then clean with the alcohol and water mixture.

- If the wall is porous, seal it before using adhesive hooks.

- Test the adhesive in an inconspicuous area to ensure it works.

| Cleaning Agent | Purpose |

|---|---|

| 50:50 mixture of IPA and water | Used to clean most wall surfaces before using adhesive hooks. |

| Degreaser | Removes stubborn grease; follow with alcohol and water cleaning. |

| Abrasion | Roughens the wall surface and removes dirt or rust. |

| Adhesion Promoters | HHelps hooks adhere better to plastic and painted surfaces. |

| Sealing | Suitable for absorbent wall surfaces such as wood and concrete. |

| Special preparation | Suitable for glass, copper, and certain plastics. |

Tip: Ensure the wall surface is completely dry before proceeding to the next step.

Application steps

Proper installation of adhesive hooks ensures the safety of the shelves and protects the wall surface. Shop owners should follow these steps:

- Peel off the protective paper from the adhesive strip.

- Press the adhesive strip firmly against the wall for 30 seconds.

- Place the hook or shelf component onto the adhesive strip. Ensure it is positioned straight.

- Wait at least one hour before hanging any items. This allows the adhesive to fully bond.

- Check the weight limit and do not exceed it.

Note: Always follow the manufacturer’s instructions for best results and to protect the wall surface.

Mistakes to avoid

Many shop owners make common mistakes when using adhesive hooks. These mistakes can lead to insecure hooks or damage to the wall. The table below lists common mistakes and their solutions:

| Mistake | Solution |

|---|---|

| Using hooks on the wrong wall | Pick the right strip for the wall. Clear strips are best for smooth walls. |

| Wall surface not properly cleaned | Clean with isopropyl alcohol. Do not use cleaning wipes. |

| Weight limit not checked | Weigh the item before choosing the adhesive strip. Do not hang excessively heavy items. |

| Operating too quickly | Allow sufficient drying time before hanging items. |

| Temperature not checked | Do not use adhesive strips when the temperature is too high or too low. |

| Using hooks in a car | Do not use adhesive hooks in a car. They cannot withstand high temperatures. |

Avoiding these mistakes will help store owners protect their walls and keep their shelves neat and tidy.

Removing adhesive hooks without damage

Tools and supplies

How can store owners remove adhesive hooks without damaging the walls? They need the right tools to do the job safely and easily:

- Hair dryer (to soften the adhesive)

- Plastic scraper or old credit card

- Rubbing alcohol

- Mild soap and water

- Commercial adhesive remover

- Soft cloth or sponge

Tip: Do not use metal tools. Metal can scratch or gouge the paint.

Safe removal steps

Properly removing adhesive hooks protects your walls. Store owners should follow these steps:

- Heat the adhesive with a hairdryer for one to two minutes. Move the hairdryer to distribute the heat evenly.

- Slowly lift one side of the adhesive hook. Slide a plastic scraper or old card under the hook to loosen it.

- Pull the adhesive hook straight off the wall. Do not pull sideways or at an angle. This can cause paint to peel or drywall damage.

- If there is any residue remaining, gently scrape it off with a plastic tool.

- Wipe the area with rubbing alcohol or an adhesive remover to remove any remaining glue.

- Wash the area with mild soap and water. Dry with a soft cloth.

Note: Do not rush or use excessive force. This can cause paint to peel or leave marks.

Cleaning residue

Sometimes, removing adhesive hooks leaves behind sticky residue. Store owners can use the following items for cleaning:

- Rubbing alcohol

- Cooking oil (vegetable or canola oil)

- Baby oil

- Peanut butter or mayonnaise

- Commercial adhesive remover

Apply a small amount to a soft cloth and gently rub the sticky area. Afterward, wash the area with soap and water.

| Common Mistake | Resulting Damage |

|---|---|

| Pulling the adhesive strip too quickly | Damage to paint or drywall |

| Not heating the adhesive | Difficult-to-remove sticky residue |

| Using sharp tools | Scratches or dents |

Store owners who follow these steps can keep their walls clean and displays neat. Properly removing adhesive hooks saves time and money.

Troubleshooting and tips

Fixing minor wall marks

Even with careful handling, adhesive hooks may leave small marks or sticky stains. Store owners can quickly address these issues.Wipe leftover glue with a soft cloth and rubbing alcohol.

- Wipe away any remaining adhesive with a soft cloth and rubbing alcohol.

- If the stain is stubborn, use a small amount of cooking oil or baby oil.

- Gently rub the area, then wash with mild soap and water. If you still see a mark, cover it with color-matching paint.

Tip:Test cleaning products in an inconspicuous area first. This helps avoid staining or discoloration.

Reusing adhesive hooks

Most adhesive hooks used for shelves are single-use. Once removed, the adhesive part cannot be reused. However, some brands, such as Command, sell extra adhesive strips. Shop owners can reuse the plastic hooks by adding new adhesive strips.

- Before reusing the hook, attach a new adhesive strip.

- Clean the wall and follow the same steps as installing a new hook.

- Do not reuse the same adhesive strip. It will not stick securely.

Note: Properly removing and installing the hooks protects the wall and keeps the shelves secure.

Preventing future damage

Shop owners can protect their walls and display shelves with a few simple measures:

- Clean the walls before installing any adhesive hooks.

- Check the weight capacity of the hooks and do not overload them.

- Remove hooks slowly and peel off the adhesive strip vertically downwards.

- Do not use hooks on damp or freshly painted walls.

| Best Practice | Benefit |

|---|---|

| Clean before applying | Hooks stick better, less mess |

| Adhere to weight limits | Prevents items from falling |

| Slow removal | Paint is less likely to peel |

Choosing the right hooks and following these tips can protect your display shelves in the long run. Using reusable hooks also reduces waste and protects the environment.

Shop owners can protect their walls by choosing the right adhesive hooks for their shelves. They need to clean the walls first and ensure the hooks are suitable for their wall type. Following the manufacturer’s instructions is crucial. Brands like IDmate offer sturdy hooks and good support. Using the correct steps will protect your display shelves and keep your walls looking good.

Precautions for using shelf adhesive hooks:

- ✅ Wipe the wall with rubbing alcohol before installing the hooks.

- ✅ Test the hooks in an inconspicuous area before full use.

- ✅ Use hooks only on smooth, finished surfaces.

- ❌ Do not use hooks on rough wood or brick walls.

- ❌ Avoid using in very hot, cold, or humid areas.

By choosing the right product and using it correctly, you can protect your walls.

FAQ

How do adhesive hooks protect store shelves and walls?

Adhesive hooks securely attach to shelves without drilling or nailing. They keep walls smooth and free of holes. Store owners rely on these hooks for quick merchandise display changes, avoiding costly repairs.

Can store owners reuse adhesive hooks after removing them?

Most adhesive hooks are best suited for single use. Some brands offer replacement adhesive strips. Store owners can reuse the plastic hooks by replacing the adhesive strips. This saves money and reduces waste.

Which surfaces are best for using adhesive hooks on shelves?

Smooth surfaces such as glass, tile, and smooth wood securely hold adhesive hooks. Rough or dusty walls can cause the hooks to fall off. Store owners should clean the surface before using the hooks to ensure optimal adhesion.

How much weight can adhesive hooks hold on merchandise shelves?

Weight limits vary depending on the brand and size of the hook. Most hooks have a weight capacity ranging from 1 to 5 pounds. Store owners should check the instructions on the packaging and never exceed the recommended weight limit to ensure shelf safety.

What should store owners do if adhesive hooks leave sticky residue?

Store owners can wipe away the residue with rubbing alcohol or cooking oil. They should use a soft cloth and gently wipe the area. The sticky residue will quickly disappear, leaving shelves and walls clean.